Molded Plywood Components

At CHK Shop Ltd., we bring your furniture designs to life with cost-effective bent plywood technology. Our process allows for the creation of innovative and versatile furniture forms, turning your design ideas into reality.

We specialize in producing bent (molded) plywood parts from high-quality beech veneer, offering a wide range of components, from serial models for school chairs to unique, original designs.

Types of Blanks: Each chair, seat, or backrest model has its own distinct structural form, so every bent plywood component is customized and agreed upon with our clients. Below, you’ll find the main types of molded plywood parts that can be used to create your chair.

Let us help you realize your vision with our expertly crafted, custom plywood components.

School Sets (Sanded, Lacquered, HPL Coated)

We specialize in producing plywood seats and backrests for school chairs. With extensive experience in manufacturing ready-to-install molded plywood kits, we are one of the few facilities capable of producing large quantities of treated parts—whether varnished, painted, or polished. We offer a variety of glued plywood forms, ensuring durability, comfort, and style for educational environments.

Chair Frame (Shell, Bucket, Monoblock)

Our one-piece seat and backrest plywood constructions serve as the essential foundation for chairs across various industries. For many manufacturers, our expertly crafted plywood shells provide strength and versatility.

Available in several variants, including CNC-milled and "pressed blanks," these shells come with an upper veneer layer in either Grade A for a high-quality finish or Grade C for upholstering. Our chair frames are designed to meet the needs of both functional and aesthetic requirements, making them a go-to choice for top furniture makers.

HoReCa Chair Parts

For creating high-quality, trend-compliant chairs in the hospitality industry, CHK Shop Ltd. offers expertly crafted front plywood parts. These components are key to achieving the perfect design for popular chair models, ensuring both aesthetic appeal and lasting durability.

We provide various treatment options, including sanding, lacquering, and veneering in a wide selection of wood types.

Inner Components (For Upholstering)

Our pressed blanks made from B-C-D grade veneer are ideal for use as inner frames for upholstered chairs, including office and lounge chairs. The strength of beech plywood makes it a reliable base for foam padding and fabric, ensuring durability and support.

Available as contour-cut or uncut blanks, these components can be customized to your needs, with options to install metal parts, T-nuts, and other mounting elements.

Other Plywood Elements

Our expertise in layer-glued bent plywood extends beyond seats and backrests. We produce legs, armrests, frames, sides, and parts for cabinet furniture, offering endless possibilities for furniture design.

By replacing solid wood components with bent plywood, manufacturers can reduce production costs while maintaining durability and aesthetic appeal. The only limit is your imagination—our plywood elements can be tailored to fit any design vision.

Additional Information:

Material: We specialize in molded plywood made from beech veneer, but can accommodate other wood types upon request.

Delivery: Understanding the complexities of Ukrainian logistics, we offer worldwide delivery for your convenience, ensuring smooth transportation of our products.

Custom Requests: For tailored solutions, send us descriptions, drawings, or photos of your desired model—there's a chance we already have the mold! Our team will quickly provide information on production possibilities, pricing, and terms of cooperation.

Let us know how we can bring your design to life with our premium bent plywood products.

THE PROCESS OF MAKING MOLDED PLYWOOD ELEMENTS:

1.

The first step in producing bent plywood is the creation of a pressing mold. You can either order a custom mold from us or provide your own. We offer a wide selection of ready-made molds, allowing you to jump straight into production, saving both time and money.

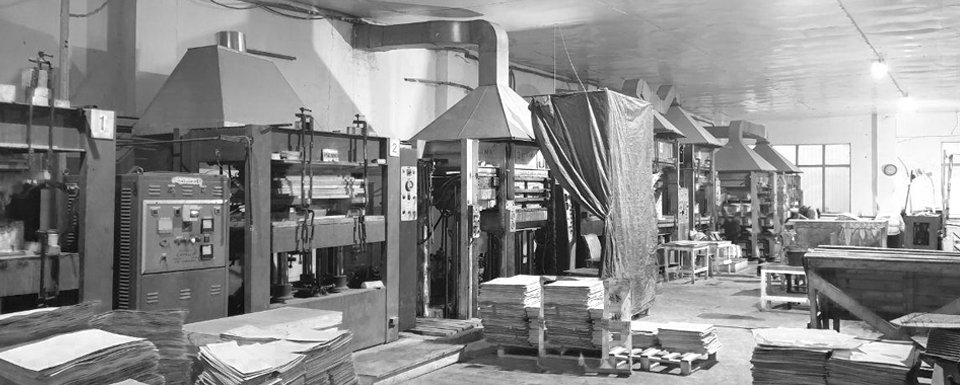

We utilize two methods for aging layer-glued blanks. Most upholstery and varnish parts are made using high-frequency presses. For complex AAA-class components, such as solid shells or parts with varied thicknesses and exposed wood, we use thermal presses. Our production fleet includes 12 high-frequency presses and 2 thermal presses to ensure precision and quality.

2.

After pressing, the plywood parts are precisely cut using milling machines or CNC machining centers. Our advanced, computer-controlled routers produce consistently uniform components, ideal for upholstery or exposed-grade products. For mold manufacturing and upholstery-grade parts, we rely on our Thermwood C-67 two-way spindle routers for impeccable results.

3.

4.

Bent glued parts requiring paints or varnishes go through an extensive processing and sanding stage. Our skilled team handles everything from surface preparation to installing metal inserts and small-scale assembly, ensuring the highest quality on every order.

5.

As an additional service, we offer a full range of finishing options. Using our semi-automated line, we apply paint, varnish, or other coatings to seats, backrests, and chair frames. All materials are high-quality and environmentally friendly, providing a polished, finished product ready for the market.